If you are in the business of manufacturing, you already understand the importance of industrial floor scales. They are not your typical type, but have useful purposes for weighing heavy items, especially when it comes to distribution. They come in handy when you have to weigh a lot of products. You can weigh large numbers at the same time, or weigh heavy-duty products without fear of damaging the appliance.

But knowing the importance of industrial floor scales in the manufacturing business is just one step. If you research them, you will come across several types. It may be confusing to know which type works best or your specific needs, and that is what this resource aims to solve.

There are a few factors that should help you select one that best suits your business. Consider the loading method; is there a way of putting heavy products on the scale without help? Will you need a forklift and if so, do you have one? Do you have the space for it and if you do, is it easily accessible? What about the accuracy? These are some of the questions to answer before choosing one.

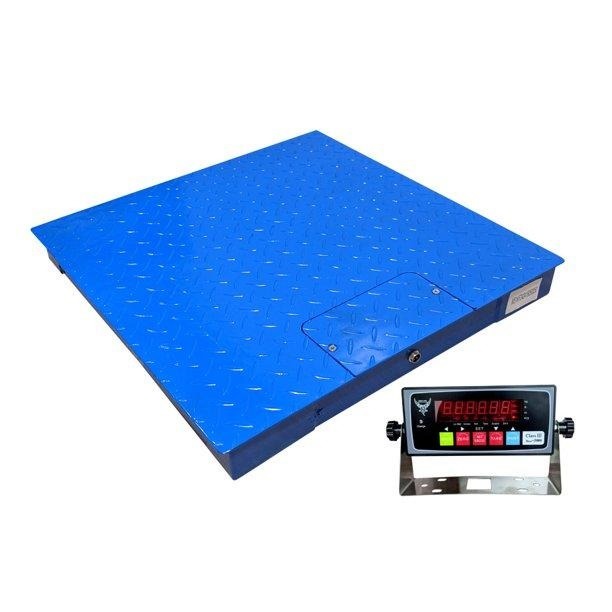

1. Low Profile Scale

A low profile industrial floor scale is precisely that, low to the floor. It is easy to load items on it because of its proximity to the ground. You may still need a ramp to lay the items, especially if they are heavy, but this type is only about an inch or two off the floor. It typically has side rails that may impede the loading of odd-shaped items, but these rails are part of the entire appliance. You can still weigh items that extend onto them and get an accurate weight.

2. Basic Scale

A basic scale is simple in design and easy to use. It typically has no designs but serves the purpose of helping you get accurate weights. With this type, you may need a ramp to load products onto it, and while this seems to be an excellent solution, bear in mind that ramps take up floor space. Also, it is not every item that easily glides up ramps, so it may take an extra effort to load the scale.

You have the option of using a pit for it. However, that means you have to construct one. Consider the effort of loading if ramps do not work and forklifts are not an option. Then, compare it to the cost of constructing a pit in the long run. It may be worth the effort if your business is in dire need of it.

3. Portable Scale

Another type to consider is the portable one. Like the low profile type, it has side rails that may affect loading and weighing. However, it has an advantage over the other type; you can move it from one point to another. The scale comes with locking casters or wheels that allow you to transport it to any area where it is needed. When it is in use, you can lock the wheels so that the scale does not roll away.

This type is ideal for places where space is an issue or where moving heavy items is not possible. It eliminates the need for having a forklift or moving trucks, ferrying products from manufacturing to packaging and shipping. All you have to do is to move it to the needed point and weight the necessary items.

You do not even need a ramp to move heavy items onto the scale. It comes designed with one, although it is split in the middle. But the design makes it easy to fold the ramp when you have to move it. However, it may not hold items that weigh a lot. The design makes it too close to the ground, and it reduces the capacity it can take. Where a basic scale can take up to 20,000lbs, this type may take only 10,000 lbs or even less at capacity. Read this article to determine how to choose the right scale.

4. Lift Scale

A lift scale functions in much the same way as other scales, but it has a significant difference. It is easier to maintain than others, making it a slightly superior one to own. If you are in the business of manufacturing chemicals or other liquid materials that may spill during transportation, this type works best for you. A basic scale may be simple enough to perform its duties and a low profile one may be ideal for easily loading items, but none of them is easy to clean.

The design is such that the top deck lifts up to expose the undercarriage. The manner of lifting the deck depends on the type you own, but most are either controlled remotely, lifted manually, or assisted by gas. The manufacturing material is heavy steel, making cleaning even simpler. If there is a spillage, all you have to do is lift the deck and clean under it. The scale is specifically designed for hygiene purposes.

5. High Precision Scale

All the scales on our list provide excellent resolutions when it comes to providing the weight of items. However, some types excel more than others in this department, and that is what you get with the high-precision type. You can click this link: https://www.hardysolutions.com/ to learn more about the uses of precision scales.

Typically, a scale produces 5,000 divisions of approved resolution and 10,000 divisions of the non-NTEP approved resolution. But this type does better than that. Suppose you weigh a 6,000lb item that has 600,000 resolutions? You may get a 6,000lb x 0.01lb readability.

Conclusion

There are many aspects of manufacturing and shipping, and having a suitable scale is one of them. Getting the most suitable scale for your specific purposes may not be a walk in the park as there are many excellent options on the market. However, if you lay some critical factors out, you may be able to narrow your choices.

Remember to choose based on the size of items, the frequency of use, precision of measurements, space, hygiene, loading method, etc. when you have them figured out, selecting one becomes much easier.